ABOUT TENOLY

Focusing on precision machine tools to help China’s high-end intelligent equipment manufacturing, Tenoly Precision Machinery has experienced engineering technology and R&D teams, always grasping the needs of the times, constantly developing new products, creating value for the industry, and providing customers with high value-added products and services.

Tenoly relies on standardized and modular design concepts to realize turning and milling composite functions. It is widely used in aerospace, aviation, shipbuilding, military industry, auto parts, new energy semiconductors, medical equipment, home appliance accessories, 3C, optics Precision parts processing in other industries.

We are engaged in one-stop ecological services in all aspects such as manufacturing, software development, talent training, and intelligent automation, and provide customers with turnkey projects. With the corporate vision of “being a benchmark in the field of turning and milling of China’s industrial mother machines”, Tenoly Precision Machinery provides customers with a solid and reliable product experience and contributes to the national industry moving to a new level.

Product

MT850B

Horizontal 5-axis Turning and Milling Center

- Efficient and precise

- Multiple processes in one

- Stable and durable

MT1650B

Horizontal 5-axis Turning and Milling Center

- Quickly switch between various processing modes

- Customized solutions

VL630B

Vertical 5-axis Turning and Milling Center

- Five-axis simultaneous

- Smart closed-loop system

- All-in-One equipment

VL800B

Vertical 5-axis Turning and Milling Center

- High precision

- High degree of automation

- Wide range of applications

106 Series

High-performance CNC Turning and Milling Center

- High rigidity

- High precision

- Heavy turning

108 Series

High-performance CNC Turning and Milling Center

- Machine tool protection

- Process improvement

- Quality and efficiency boost

208 Series

High-performance CNC Turning and Milling Center

- Heavy-duty casting base and components

- High-speed spindle unit

210 Series

High-performance CNC Turning and Milling Center

- Automatic tool changer

- Automated and efficient mass production

250L10 Series

Heavy-Duty CNC Turning and Milling Center

- Low-speed heavy-duty turning capabilities

- 30° slanted back, integrated box-type structure

250L15 Series

Heavy-Duty CNC Turning and Milling Center

- Equipped with a high-performance spindle

- Fully hardened rail construction, suitable for heavy-duty turning

250L20 Series

Heavy-Duty CNC Turning and Milling Center

- High-efficiency powered turret

- Low center of gravity, high stability and precision

- Full hard rail structure

250L30 Series

Heavy-Duty CNC Turning and Milling Center

- Max. rotation diameter 860mm

- Max. processing diameter 570mm

- Max. processing length 3000mm

- Suitable for heavy turning

600 Series

Mainstream Turning and Milling Center

- Stable high-rigidity structure

- High-precision spindle unit

- Unique turret design

- Suitable for heavy turning

1200 Series

Mainstream Turning and Milling Center

- High rigidity

- High torque

- High efficiency

- High performance

2000 Series

Mainstream Turning and Milling Center

- Smoother contour processing and smoother surfaces.

- Suitable for machining complex curved surfaces.

3000 Series

Mainstream Turning and Milling Center

- Modular design combination

- Excellent design

- Powerful performance

- High rigidity, heavy turning

Our core competitiveness is provide comprehensive solutions for fixtures, tools, process applications, and automation. Our factory also has a global sample center that can provide customers with services such as sample production and batch trial production, ensuring that products meet customer customization requirements until they are delivered to their satisfaction.

TENOLY

A TRUSTWORTHY CHOICE

Value-added Services: Tenoly Precision Machinery not only provides customers with diversified solutions, professional application training, and high-quality after-sales service, but also helps customers resolve product processing difficulties and fully meet their customized needs.

Consulting Services: We offer customized VIP corporate consulting solutions, including training opportunities, case-by-case process analysis support, discounts, and seamless integration with various machine tools.

After-sales Guarantee: We are committed to your consideration and service. We hope that you will become our loyal supervisor and inspector, providing comprehensive verification of product quality and service quality. We will continue to improve and enhance our services.

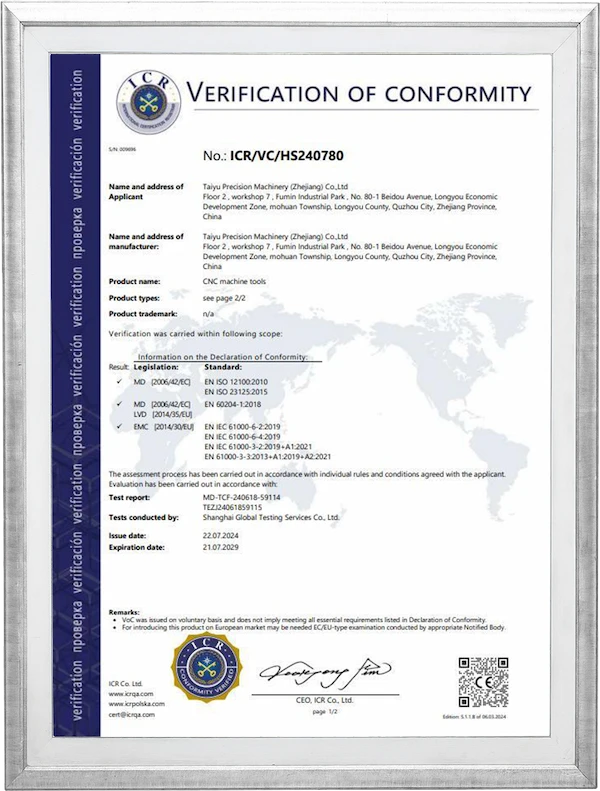

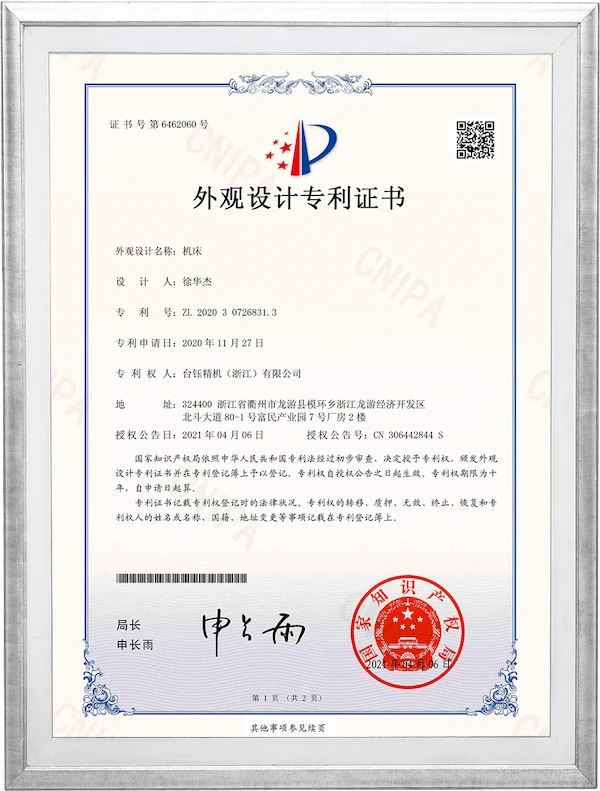

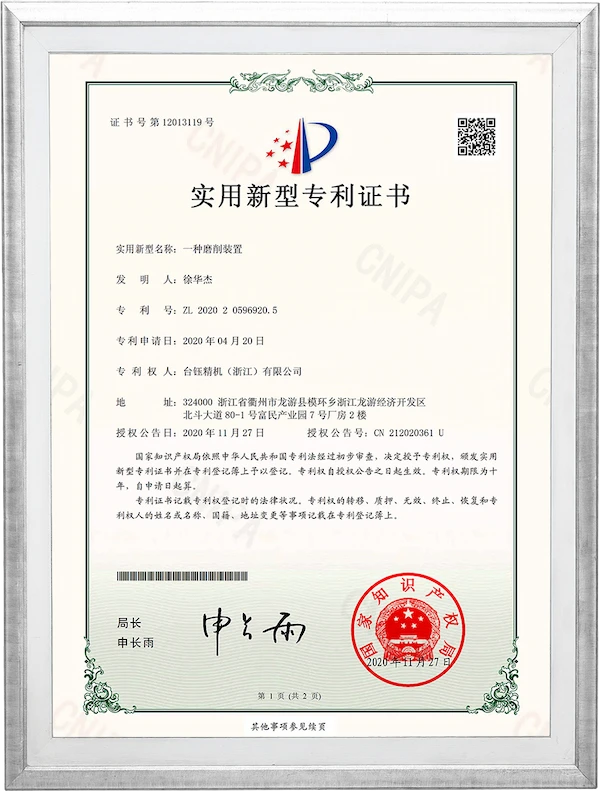

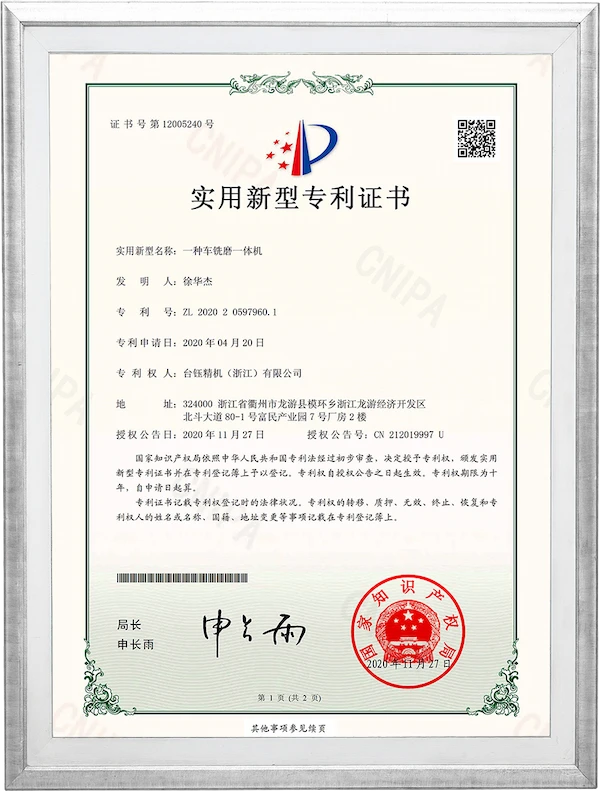

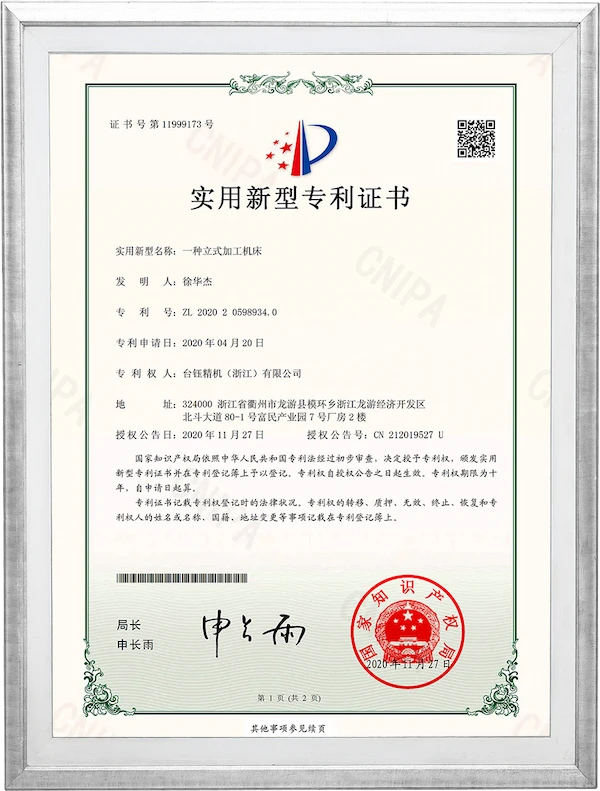

CERTIFICATION

Meet the processing needs of multiple industries

Our products are widely used in the automotive, new energy, battery, optoelectronics, artificial intelligence, precision electronics, power tools, medical, communications and other technology industries...

FAQs

Frequently Asked Question.

Our FAQ section helps you quickly find answers to your questions about products, orders, and services. If your questions aren’t answered, please contact customer service.

Our main products include 5-axis turning and millling center, CNC turning center, and milling and grinding equipment. We also provide professional supporting services in fixtures, turning tools, process technology, and automation solutions.

We manufacture machine in Zhejiang Province, China, and we have a global prototyping center offering services such as sample production and small-batch trial production. We welcome your visit.

We have a complete, closed-loop industrial chain, encompassing housing sheet metal, spindle development, 5-axis machining equipment, and related casting. We also have dedicated inspection processes, including dynamic balancing, temperature rise, and noise testing, to ensure stable performance.

15 to 60 working days

We support a machine purchases (some low-cost machines may have different requirements; please contact us to confirm the conditions).

Freight is the buyer’s responsibility (the specific amount depends on the region, shipping method, quantity, and delivery conditions).

OUR BLOG & NEWS

Tenoly’s blog area brings together the latest industry trends, practical technology sharing and in-depth insights. Whether you are a novice in the industry or a senior expert, you can find valuable content.

How to Achieve Breakthroughs in Efficiency and Cost Control in Hardware Processing Using CNC Lathe?

CNC lathe have significantly improved the precision and efficiency of the hardware processing industry, enabling the stable mass production of a large number of rotating parts...

Read MoreHow to Achieve Breakthroughs in Efficiency and Cost Control in Hardware Processing Using CNC Lathe?

CNC lathe have significantly improved the precision and efficiency of the hardware processing industry, enabling the stable mass production of a large number of rotating parts...

Read MoreHow To Reduce Friction Errors in CNC Turning and Milling Composite Machining Center?

CNC turning-milling composite machining centers are highly integrated CNC machine tools capable of performing multiple operations such as turning, milling...

Read MoreToolpath Planning in CNC Turning Center

Toolpath planning in CNC turning centers determines machining efficiency, surface quality, and tool life, directly impacting the high-precision production of aerospace...

Read More